Isolated foundation for active vibration damping for power presses, forging hammers, engine test rigs, and passive vibration isolation of machining centres, grinding machines, measuring & testing equipments, laser cutters and microscopes.

The ISOLATED FOUNDATION is required to reduce both active and passive vibrations. Vibration isolation mountings are required to reduce the transmission of vibration and shocks.

A foundation block or Vibration isolation mountings for high dynamic machines like power press, forging hammers, compressors, engine test rigs etc. is required in order to reduce the transmission of vibration and shock to nearby precision machines / building structures. To control the source of vibration disturbance through the use of resilient insulating materials is known as ACTIVE VIBRATION ISOLATION.

When it is not possible to prevent or sufficiently lower the transmission of shock and vibration from the source, a resiliently supported vibration insulating foundation block can be used for the PASSIVE VIBRATION ISOLATION of sensitive equipments like Machining Centres, Measuring and Testing Machines / Equipments etc.

ISOLATED FOUNDATION lowers the centre of gravity of the machine foundation system and adds to the stability of the machine. Machine remains aligned during dynamic load changes and rapid movements within the machines.

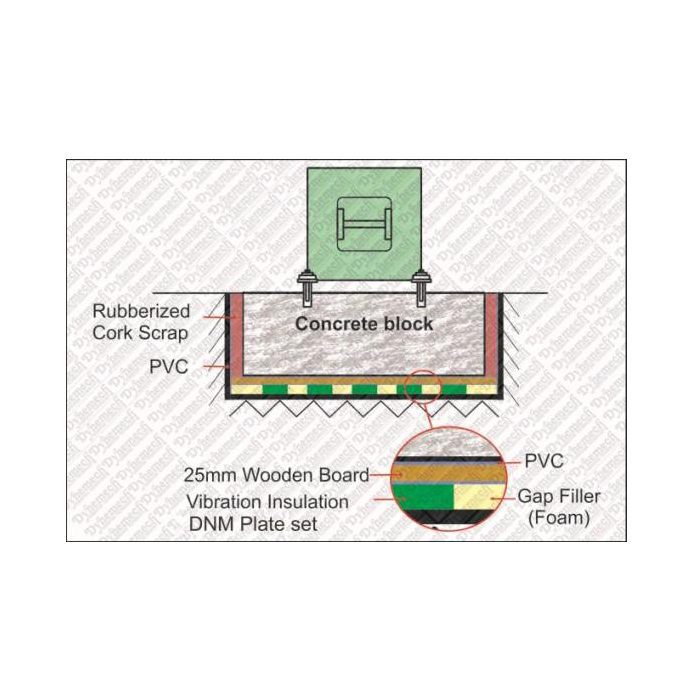

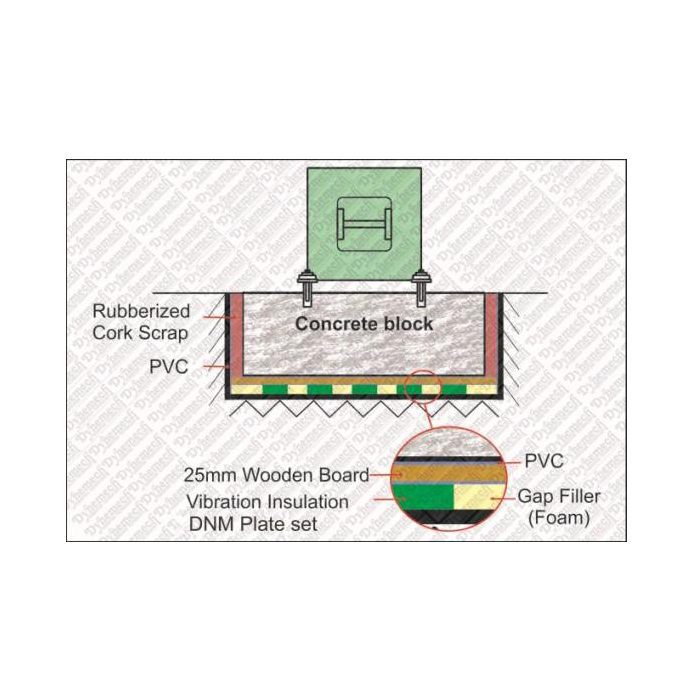

CONSTRUCTION OF THE ISOLATED FOUNDATION

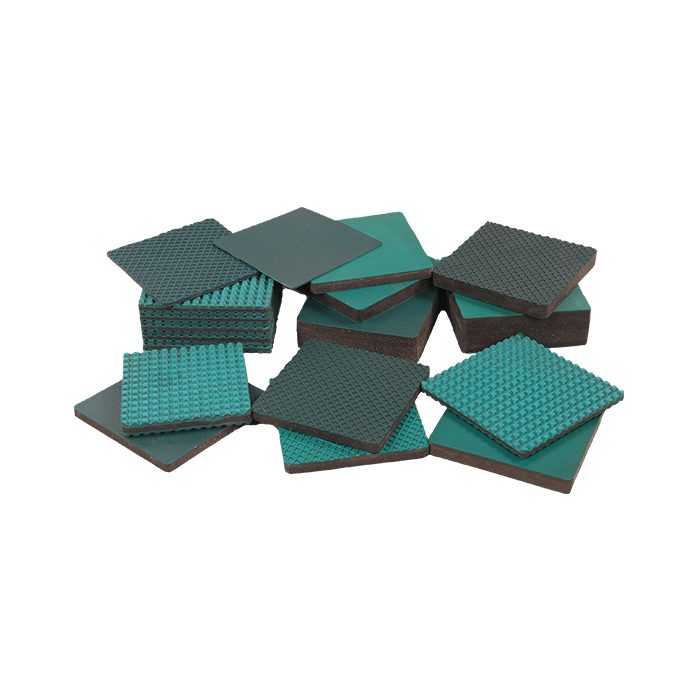

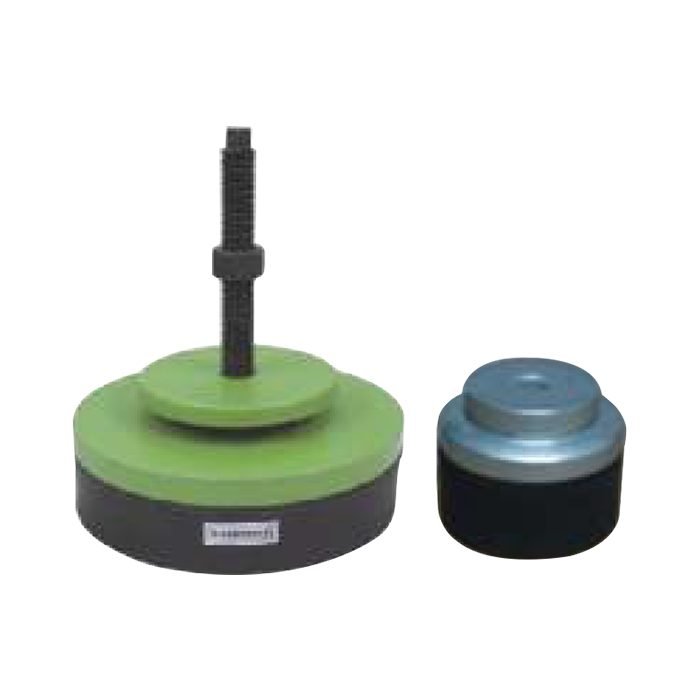

Construction of the Foundation Tub should be carried out under the supervision of a Civil Engineer/ Contractor. Foundation must be 100% water-proof. The pit should be made to a depth as per the ground condition. The inner surface of the pit should be smooth. As per the layout supplied by DYNEMECH, place the vibration damping plates sets and gap filler in the pit. Paste them to the pit surface (i.e the base and the side walls) with the adhesive. Seal the joints with the adhesive tape supplied by DYNEMECH. Place a layer of PVC Sheet over the entire pit surface on the base and side walls. The PVC films should overlap. Seal the joints. Put a wooden ledge on the top of the foundation upto the ground level, which will be latter removed for creating gap for Polymeric Sealant, for preventing the water from entering the pit from ground. Place a layer of 5mm thick fibre board, which should be overlapped and joints sealed with the adhesive tape. A layer of wooden ply should be placed on the entire pit surface overlapped and the joints should be sealed with adhesive tape. Place another layer of PVC sheet over the entire pit surface on the base and side walls. The PVC films should overlap. Seal the joints. Pour concrete upto the depth of 15mm amd allow it to dry, which acts as a compression plates.Afetr drying of the compression plates, erect reinforcement and pour concrete in the rest of the pit area.For concrete layer deeper than 700mm, concrete should be poured in the layers of 300mm. The foundation block and the tub should not be in contact with each other. Now, remove the wooden ledge and fill the gap with polymeric sealent. Place the machine over the concrete block and levelling should be done with the help of edge mounts or screw support mounts.